Despite common perceptions, manufacturing in the U.S. isn’t just about nostalgia for a bygone era; it’s a robust and dynamic sector in today’s economy. As of 2022, the manufacturing industry contributed $2.35 trillion to the nation’s GDP, highlighting its critical role in economic growth. This considerable impact, however, is often overshadowed by the focus on emerging technologies and service-based industries.

The U.S. has a rich history in manufacturing, dating back to the industrial revolution which solidified its prominence. Today, advanced manufacturing technologies like AI and IoT are revolutionizing production processes, leading to increased efficiency and innovation. Interestingly, manufacturing jobs have also evolved, requiring more specialized skills and higher education levels, indicating a sector not in decline but transformation.

Historical Overview of Manufacturing in the U.S.

The Early Days: Pre-Industrial Revolution

Before the Industrial Revolution, most U.S. manufacturing happened in small workshops and homes. These were very basic and labor-intensive setups. Early American manufacturing relied heavily on skilled craftsmen and manual labor.

The use of tools and simple machinery was common. This period set the foundation for future industrial developments. It was a time when quality craftsmanship was highly valued.

The Rise of Factories: Industrial Revolution

The Industrial Revolution, starting in the late 18th century, brought major changes. Factories began to replace workshops, allowing for mass production. This era saw the introduction of steam engines, which significantly boosted productivity.

Key inventions like the cotton gin and spinning jenny were game-changers. These innovations made manufacturing faster and more efficient. As a result, the U.S. economy began to grow rapidly.

The 20th Century: Technological Advancements

The 20th century saw huge advancements in manufacturing technology. The assembly line, popularized by Henry Ford, revolutionized the auto industry. This method was soon adopted by other sectors as well.

World War II further sped up technological progress. Factories were crucial for producing war supplies. After the war, many of these technologies were adapted for peacetime use.

Modern Era: Digital Transformation

Today, U.S. manufacturing is in the midst of a digital revolution. Advanced technologies like AI, IoT, and robotics are transforming the industry. These innovations are making manufacturing more efficient and less labor-intensive.

Smart factories are now a reality, where machines communicate with each other for better coordination. This shift is helping the U.S. remain competitive on the global stage. The focus is now on sustainability and innovation.

The Current State of U.S. Manufacturing

The U.S. manufacturing sector remains a cornerstone of the economy. Despite competition from global markets, it continues to thrive. Modern technology plays a vital role in its ongoing success.

Automated factories and smart manufacturing techniques are becoming more common. This shift helps improve productivity and reduce costs. It’s an exciting time for the industry.

However, challenges persist. Companies face issues such as supply chain disruptions and labor shortages. These hurdles require innovative solutions.

On the bright side, manufacturing in the U.S. is becoming more sustainable. Many firms are adopting green practices to reduce their environmental impact. This move aligns with global trends towards sustainability.

Technological Innovations in Manufacturing

Advancements in technology are reshaping the manufacturing landscape. Artificial Intelligence (AI) and the Internet of Things (IoT) are leading this change. These technologies increase efficiency and precision.

For example, AI can predict equipment failures before they occur. This helps prevent costly downtime. Similarly, IoT allows machines to communicate with each other for seamless operations.

Robotics also play a significant role. Robots are now capable of performing complex tasks with high accuracy. This reduces the need for human labor in dangerous or repetitive jobs.

Economic Impact and Job Market

Manufacturing remains a crucial part of the U.S. economy. It contributes significantly to GDP and provides numerous jobs. The industry’s impact is felt across various sectors.

However, the job market is evolving. There is a growing demand for skilled workers. Specialized training and education are becoming essential to keep up with technological advancements.

Many manufacturing jobs now require knowledge of advanced machinery and software. This shift necessitates a focus on workforce development to bridge the skills gap.

Sustainability Practices in Manufacturing

Companies are increasingly focusing on sustainable practices. Efforts are being made to reduce carbon footprints and waste. This is essential for environmental conservation and regulatory compliance.

Renewable energy sources are being integrated into manufacturing processes. Solar and wind power are popular choices. These alternatives help reduce reliance on fossil fuels.

Additionally, recycling and reusing materials are becoming standard practices. This not only minimizes waste but also cuts costs. The move towards sustainability is both an ethical and economic necessity.

Economic Impact of Manufacturing in the U.S.

The manufacturing sector plays a crucial role in the U.S. economy. It contributes over $2.3 trillion to the nation’s GDP each year. This shows how vital the industry is to economic growth.

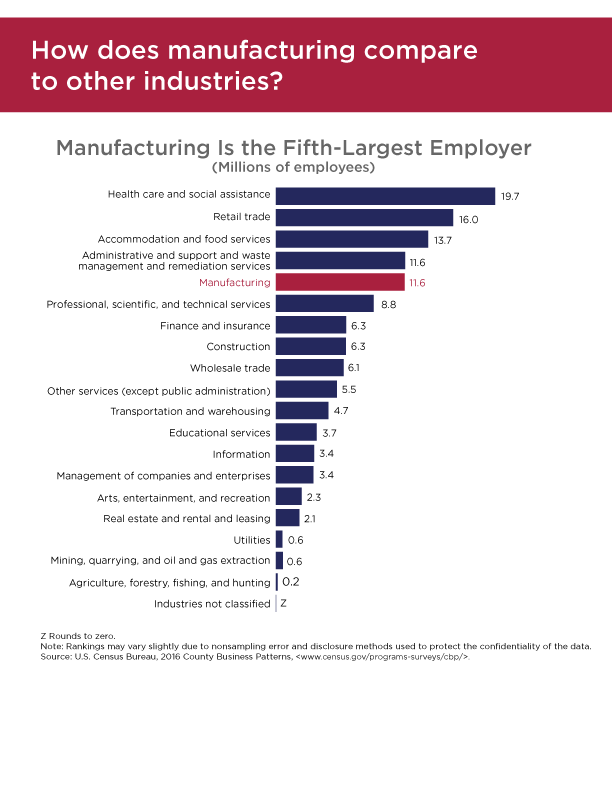

Manufacturing also provides millions of jobs. In 2021, it employed around 12.5 million workers, making it a significant source of employment. These jobs are often higher-paying compared to other industries.

The sector also stimulates other parts of the economy. It supports various services, from logistics to retail. This creates a multiplier effect, boosting overall economic activity.

Additionally, U.S. manufacturing is essential for international trade. It accounts for a large portion of the country’s exports. This helps balance trade deficits and strengthens the economy.

- Contributes over $2.3 trillion to GDP

- Employs around 12.5 million workers

- Boosts other industries through a multiplier effect

- Accounts for a large portion of U.S. exports

The Role of Technology in Modern Manufacturing

In modern manufacturing, technology is a game-changer. It improves efficiency and reduces costs. Advanced technologies like AI, IoT, and robotics are leading the way.

Artificial Intelligence (AI) helps predict equipment failures. This prevents costly downtime and ensures smooth operations. AI also aids in quality control and product design.

The Internet of Things (IoT) is another significant player. IoT-connected devices communicate with each other. This seamless interaction enhances process automation and real-time monitoring.

Robotics are crucial in modern manufacturing. Robots perform complex tasks with high precision. This reduces the need for human labor in hazardous environments.

3D printing is revolutionizing production methods. It allows for rapid prototyping and customization. This technology speeds up the development cycle and lowers production costs.

Technology also enables sustainable practices. For example, energy-efficient machinery and renewable energy sources are becoming more common. These innovations help reduce the environmental impact of manufacturing.

- Improves efficiency and reduces costs

- AI predicts equipment failures and aids in quality control

- IoT enhances process automation and real-time monitoring

- Robotics perform complex tasks with precision

- 3D printing allows for rapid prototyping

- Enables sustainable practices

Manufacturing Jobs: Evolution and Expectations

Manufacturing jobs have changed dramatically over the years. In the past, they required more manual labor and less education. Today, technology has transformed these roles, demanding new skills.

Modern manufacturing jobs often require expertise in computer systems and robotics. Workers need to understand complex machinery and advanced software. This shift has led to higher educational requirements.

With the rise of automation, some traditional jobs have become obsolete. However, new roles have emerged, such as robot technicians and data analysts. These positions focus on maintaining and optimizing automated systems.

Companies now look for employees with a mix of technical and soft skills. Problem-solving and adaptability are key traits. The ability to work with technology and collaborate with others is essential.

The pay in manufacturing jobs has also evolved. Higher skill levels often lead to better wages. This attracts more people to pursue careers in the industry.

- Manual labor roles are decreasing

- Technical knowledge is increasingly important

- Automation creates new job opportunities

- Employers value problem-solving and adaptability

- Higher skill levels result in higher pay

Challenges Faced by the U.S. Manufacturing Industry

The U.S. manufacturing industry faces several challenges today. One major issue is supply chain disruptions. These disruptions can delay production and increase costs.

Another challenge is the shortage of skilled labor. As technology advances, the demand for highly skilled workers grows. This gap makes it challenging to find qualified employees.

Trade policies also impact the industry. Tariffs and trade restrictions can make raw materials more expensive. This drives up production costs and affects competitiveness.

Environmental regulations are becoming stricter. While they are essential for sustainability, compliance can be costly for manufacturers. Companies need to invest in cleaner technologies to meet standards.

Competition from global markets is fierce. U.S. manufacturers must innovate to stay ahead. Keeping up with international competitors requires constant improvement and adaptation.

- Supply chain disruptions delay production

- Skilled labor shortage hinders growth

- Trade policies increase raw material costs

- Environmental regulations are costly

- Intense global competition requires innovation

Case Studies: Successful U.S. Manufacturing Firms

Many U.S. manufacturing firms have achieved significant success. Tesla is a prime example, revolutionizing the auto industry with electric cars. Their focus on innovation and technology sets them apart.

Boeing is another success story. As a leading aerospace manufacturer, they produce advanced aircraft and spacecraft. Their commitment to research and development drives their growth.

Caterpillar excels in heavy machinery production. Known for robust construction equipment, they’ve maintained market leadership through quality and reliability. Innovations in engineering strengthen their position.

John Deere shines in agriculture manufacturing. Their high-quality farming equipment helps farmers worldwide increase productivity. Continual advancements keep them ahead of competitors.

- Tesla – Electric vehicle innovations

- Boeing – Advanced aerospace technologies

- Caterpillar – Robust construction equipment

- John Deere – High-quality farming machinery

| Company Name | Industry Focus | Key Innovations | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tesla | Automotive | Electric Vehicles, Battery Technology | ||||||||||||

| Boeing | Aerospace | Advanced Aircraft, Spacecraft Development | ||||||||||||

| Caterpillar Inc. | Construction Machinery | Robust Equipment Design, Engineering Solutions | ||||||||||||

| John Deere< / td > | Agricultural Machinery< / td > | Precision Farming Equipment< / td > < / tr > यार कोई मेरी मदद कर दो ना’ t’dbm stdfplt է այօ՛-ի ֆկդդս t-ọ- ID! Predictions and Future Trends in U.S. ManufacturingThe future of U.S. manufacturing looks promising with emerging technologies. One major trend is the rise of smart factories. These factories use interconnected machines to optimize production processes. Another trend is the increasing use of AI and machine learning. These technologies help predict maintenance needs and improve quality control. They make operations more efficient and cost-effective. Sustainability will be a significant focus. Companies are investing in green technologies to reduce their carbon footprint. This shift will be crucial for staying competitive in a global market. Customization and on-demand manufacturing are becoming popular. Technologies like 3D printing allow for rapid prototyping and personalized products. This trend caters to consumer demands for unique and custom-made items.

Global collaboration will also increase. U.S. manufacturers will work with international partners for innovation. This trend will lead to shared knowledge and improved technologies. The workforce will need to adapt to these changes. There will be a demand for more skilled workers trained in advanced technologies. Education and training programs will be essential for preparing the next generation of workers.

Frequently Asked QuestionsThe U.S. manufacturing industry is complex and ever-evolving. Here are some common questions experts frequently ask about this vital sector. 1. How has technology impacted U.S. manufacturing?Technology has significantly transformed U.S. manufacturing by enhancing efficiency and reducing costs. Innovations like artificial intelligence (AI), the Internet of Things (IoT), and robotics have made production processes more precise and automated. This technological shift has led to smarter factories where machines communicate seamlessly with each other. As a result, production lines can now operate 24/7 with minimal human intervention, boosting overall productivity. 2. Why is there a labor shortage in the manufacturing sector?The labor shortage in U.S. manufacturing stems from several factors, including an aging workforce and rapid technological changes. Many experienced workers are retiring, while younger generations lack interest in traditional manufacturing roles. The increasing complexity of modern manufacturing requires specialized skills that many current workers do not possess. Training programs and educational initiatives are essential to bridge this skill gap and attract new talent to the industry. 3. What role does sustainability play in modern manufacturing?Sustainability is becoming increasingly important in modern manufacturing as companies strive to reduce their environmental impact. By adopting green technologies and practices, manufacturers aim to minimize waste, lower carbon emissions, and conserve resources. This shift not only aligns with global trends towards sustainability but also helps companies comply with stricter environmental regulations. Additionally, sustainable practices can improve a company’s brand image and appeal to environmentally conscious consumers. 4. How do supply chain disruptions affect the manufacturing industry?Supply chain disruptions can severely impact the manufacturing industry by causing delays in production and increasing costs. When raw materials or components are unavailable, manufacturers may face significant downtime while waiting for supplies. This issue became particularly evident during global events such as the COVID-19 pandemic, which disrupted supply chains worldwide. To mitigate such risks, manufacturers are exploring strategies like diversifying suppliers and increasing local sourcing. 5. What are some emerging trends in U.S. manufacturing?Emerging trends in U.S. manufacturing include the increased use of AI, IoT, robotics, and 3D printing technologies. These advancements make production more efficient, customizable, and adaptable to changing market demands.

Additionally , smart factories are on the rise . These facilities use interconnected systems for real-time decision-making , optimizing operations ,and reducing waste . The focus on sustainability continues ,with more companies investing ingreen initiatives . ConclusionThe state of manufacturing in the U.S. is both dynamic and resilient. With the integration of advanced technologies like AI, IoT, and robotics, the industry is poised for a bright future. However, addressing challenges such as labor shortages and supply chain disruptions remains crucial. Sustainability and innovation will continue to drive the sector forward. As companies adopt greener practices and smarter systems, the U.S. manufacturing landscape will evolve to meet global demands. The potential for growth and success in this key industry remains promising.

Add A Comment

|